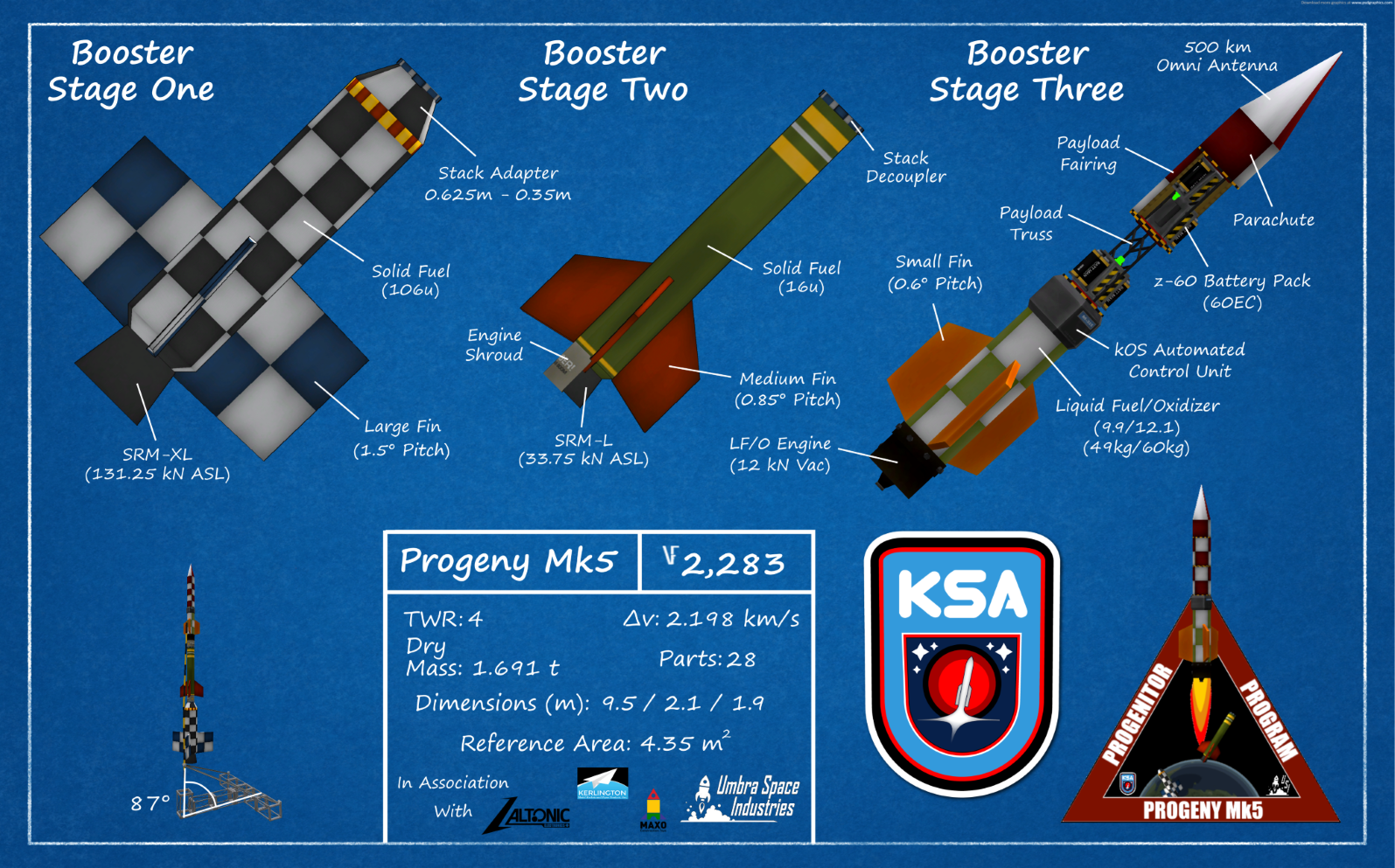

With the retirement of the Mk4 today, all focus is now being directed at its successor, the Mk5, which has been developed in parallel with the Mk4 over the last few months. Structurally similar to the Mk4, the Mk5’s main difference will be in how it is operated thanks to a new control unit that will be integrated more with the rocket to allow monitoring of and commands to be sent to internal systems. This unit is “inline”, meaning it will be a component of the rocket body rather than attached to one of the payload trusses, freeing up space which has been used to add additional battery power as this control unit requires more electric charge to run its operations (the amount of charge needed depends on the size of the instructions loaded). Slightly larger than the 0.35m width of the rocket, it has been placed below the payload near the fins to help with trans-sonic stability. The initial launch series will see five rockets head for space within 2 weeks on these dates:

With the retirement of the Mk4 today, all focus is now being directed at its successor, the Mk5, which has been developed in parallel with the Mk4 over the last few months. Structurally similar to the Mk4, the Mk5’s main difference will be in how it is operated thanks to a new control unit that will be integrated more with the rocket to allow monitoring of and commands to be sent to internal systems. This unit is “inline”, meaning it will be a component of the rocket body rather than attached to one of the payload trusses, freeing up space which has been used to add additional battery power as this control unit requires more electric charge to run its operations (the amount of charge needed depends on the size of the instructions loaded). Slightly larger than the 0.35m width of the rocket, it has been placed below the payload near the fins to help with trans-sonic stability. The initial launch series will see five rockets head for space within 2 weeks on these dates:

Flight 1: 9/12 @ 23:23 UTC Flight 4: 9/20 @ 17:49 UTC

Flight 2: 9/14 @ 17:29 UTC Flight 5: 9/22 @ 17:56 UTC

Flight 3: 9/18 @ 23:43 UTC Future launches on demand from clients within 2 weeks

These dates and times are subject to change of course in the event of any delays but they represent the best-case scenario for launching all five rockets.

As noted in the sixth launch slot, once the initial five launches are completed the Mk5 should be well-developed enough to begin accepting contracts from agencies that want data from low-Kerbin space. Umbra Space Industries will be spending the remainder of this month and most of next getting their production facilities setup to produce Mk5 components more rapidly now that specifications and equipment are becoming set. The Vertical Assembly Building is likewise finishing up their assembly pipeline for efficient construction. Once a contract is signed we can have the rocket boosters manufactured and the vehicle assembled in 2 weeks for launch.

The design of the Mk5 only differs from the original Mk4 in the 3rd stage, which sports the new inline control unit and the dual-stacked payload trusses introduced late in the Mk4’s development. Fin angles specified are from the 3rd flight of the Mk4, which had the least amount of precession for the 3rd stage during ascent and re-entry. Although the angles were flown with a faster-moving 6G launch, the longer burn times from the lower-thrust booster will still allow for decent spin rates to build up. Launching at 4Gs, the rocket will only pitch up about 1° so we are tilting the launch base to only 3° from vertical to help raise the apokee. It’s also important to note the mass, cost, part count and Δv are all based on having no payload instruments aboard.

The design of the Mk5 only differs from the original Mk4 in the 3rd stage, which sports the new inline control unit and the dual-stacked payload trusses introduced late in the Mk4’s development. Fin angles specified are from the 3rd flight of the Mk4, which had the least amount of precession for the 3rd stage during ascent and re-entry. Although the angles were flown with a faster-moving 6G launch, the longer burn times from the lower-thrust booster will still allow for decent spin rates to build up. Launching at 4Gs, the rocket will only pitch up about 1° so we are tilting the launch base to only 3° from vertical to help raise the apokee. It’s also important to note the mass, cost, part count and Δv are all based on having no payload instruments aboard.

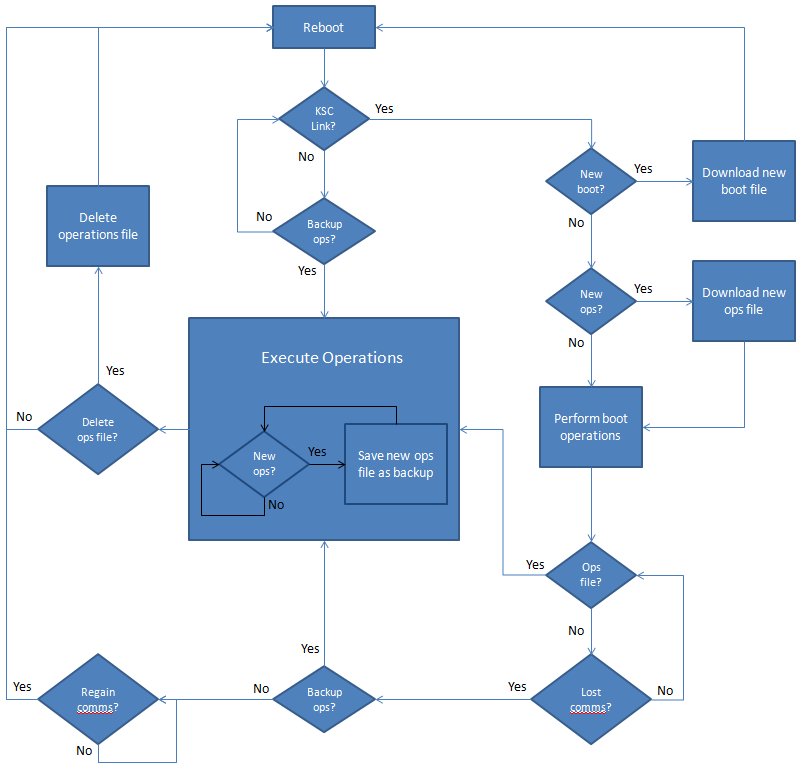

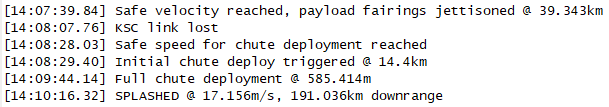

The development of the automated control scripts has been ongoing over the past few months, and over these first 5 launches we will be gradually testing the software. The first launch will still be done under manual control, but the scripts will be loaded and monitoring the rocket, simulating their operation. We will be able to analyze their log outputs afterwards to determine whether the code was sending the proper commands at the proper times. The second launch will see partial or full control depending on how well the scripts ran on the first launch. The remaining launches will be used to further test & resolve any issues that arise, as well as tweaking the ascent profile of the 3rd stage. We will be releasing more information on the scripts in future posts, and all scripts will be hosted on our Github.

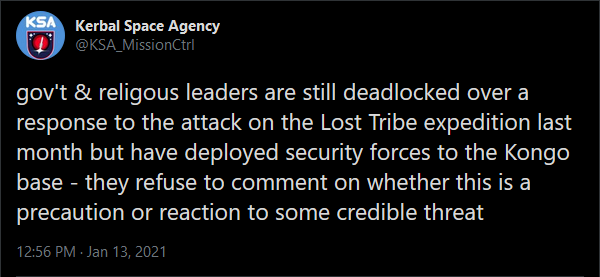

Some additional information was also released via our twitter account during the administration meeting earlier today.